Waterproofing and DWR

Understanding Waterproofing, DWR, and How to Maintain Your Dry Gear

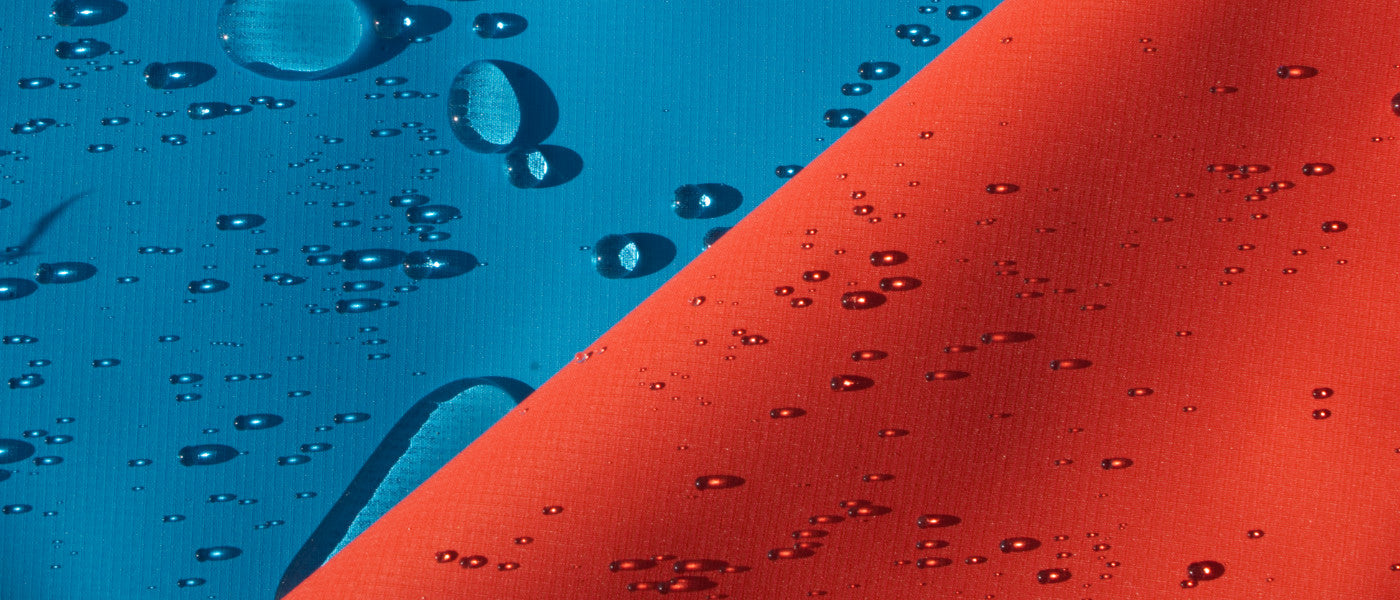

From time to time, customers reach out to us with concerns that the "waterproofing" on their dry suit or dry top has worn off, asking how they can restore it. Since "waterproofing" in this context can be misleading—suggesting that an outer coating or finish is responsible for keeping the garment dry—we want to clear up some misconceptions about how waterproof-breathable fabrics function. We'll also cover why garments may appear to be soaking through and what you can do about it.

How Waterproof-Breathable Fabrics Work

Most dry tops and dry suits are made from three-layer fabric, consisting of:

-

An outer shell for durability

-

A mid-layer waterproof-breathable membrane that provides the actual waterproof barrier

-

An inner tricot lining that protects the delicate waterproof layer

Additionally, nearly all waterproof-breathable fabrics include a Durable Water Repellent (DWR) coating applied to the outer shell. This DWR treatment helps water bead up and roll off the surface, preventing the fabric from absorbing moisture. However, DWR does not make a garment waterproof—its main job is to keep the outer shell from "wetting out," which can affect both breathability and comfort.

Why Does My Dry Suit Feel Wet?

When the DWR coating wears off, the outer shell can start to absorb water instead of repelling it. This leads to two common issues:

-

Reduced breathability – A soaked shell traps moisture inside the garment, making it harder for sweat and vapor to escape.

-

Increased condensation – A wet outer fabric gets colder, which can cause moisture inside the garment to condense, making it feel damp even though no water has actually leaked through.

These factors often lead people to believe their gear is leaking, when in reality, the garment remains fully waterproof.

The Shift in DWR Technology and Its Legal Landscape

In recent years, powerful long-chain C8-based DWR finishes—once industry standard—have been phased out due to environmental and health concerns. These treatments contained PFAS (per- and polyfluoroalkyl substances), known as "forever chemicals", which persist in the environment and have been linked to serious health risks.

As a result:

-

The U.S. Environmental Protection Agency (EPA) and the European Union (EU) have banned or restricted many older DWR coatings.

-

Outdoor brands, including Immersion Research, have moved to legal, safer alternatives that comply with evolving environmental regulations.

-

Modern DWR coatings are less durable than their predecessors, meaning more frequent maintenance is required to maintain water repellency.

At Immersion Research, we are committed to providing exceptional gear while meeting legal and environmental standards. We ensure that our products use compliant, sustainable DWR treatments while still delivering the best possible performance.

How to Restore DWR Performance

DWR coatings naturally degrade over time due to dirt, oils, and abrasion. The good news is that you can restore some water repellency with after-market treatments, such as Revivex, which is available on our website and at most outdoor retailers.

There are two primary application methods:

-

Spray-on DWR – Preferred for targeted reapplication, especially on high-wear areas like PFD strap contact points.

-

Wash-in DWR – Treats the entire garment but can waste product by coating the inside as well.

For best results, wash your gear with a cleaner designed for waterproof-breathable fabrics. After washing, it’s safe to put your gear in the dryer on low heat to help restore water repellency.

Then apply a spray-on DWR when your garment starts to show signs of wetting out. However, if a garment no longer beads water at all, full restoration is difficult, and results won’t last as long as the factory-applied finish.

Choosing the Right Fabric for Long-Term Performance

When selecting a new dry suit or top, consider the type of outer shell material:

-

Polyester – Naturally more hydrophobic, meaning it sheds water faster and resists saturation. However, it is less abrasion-resistant than nylon.

-

Nylon – Stronger and more durable but more hydrophilic, meaning it absorbs more water unless treated with DWR.

Even with the best materials, maintaining DWR performance is key to maximizing the longevity and comfort of your gear.

Keeping Your Gear Performing at Its Best

Regular maintenance helps extend the life of your dry wear. Here are a few tips:

-

Keep it clean – Dirt and oils can reduce the effectiveness of DWR. Before assuming it’s worn out, wash your gear with a cleaner designed for waterproof-breathable fabrics. After washing, it’s safe to put your gear in the dryer on low heat to help restore water repellency.

-

Reapply DWR as needed – Touching up water-repellent coatings can keep your gear performing longer.

-

Know when it’s time to upgrade – If your gear has lost its ability to shed water and maintenance isn’t restoring it, consider a new garment with improved materials and design.

At Immersion Research, we’re constantly innovating to create durable, high-performance gear while remaining environmentally responsible. While today’s legal DWR options may not last as long as past versions, we are committed to offering the best possible solutions to keep you dry and comfortable on the water.

Still have questions?

Reach out to our customer service team. We're here to help.